Animal Feed Factory Automation

- Optimum processes

- Minimum downtime

- Auditable production

Our services

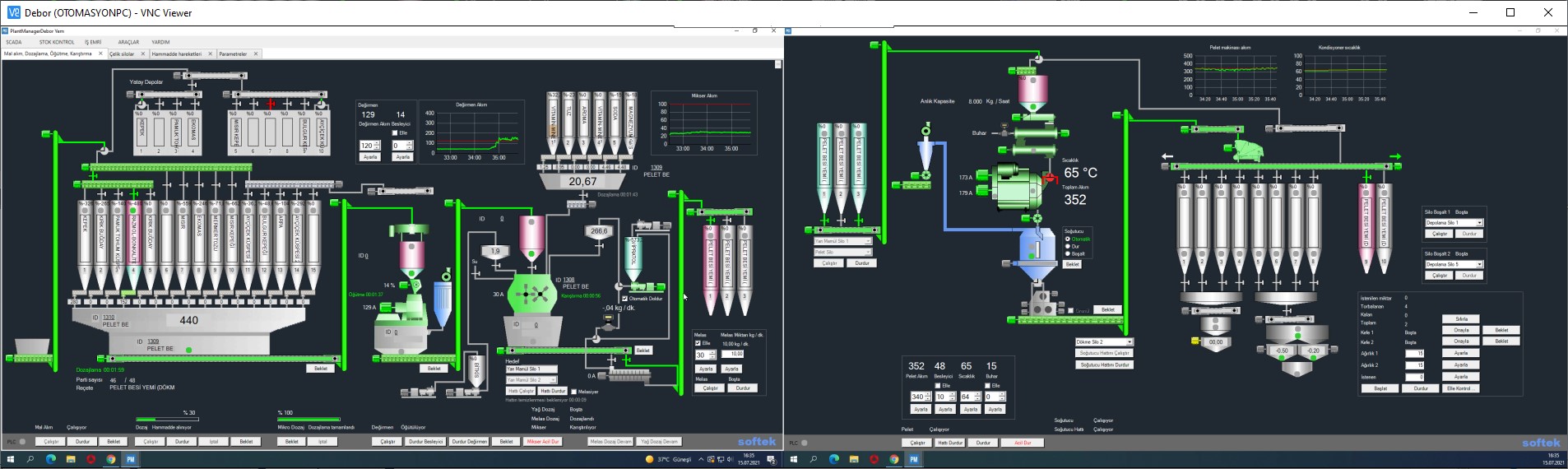

- Development of PLC, SCADA, management and integration software

- Development of MCC and PLC projects, production of panels in desired IP class

- Consulting for the selection of sensors, wiring systems, electromechanical and pneumatic devices,

- Cabling, commissioning, process optimization

- Modernization of manual or semi-automatic facilities

- 7x24 maintenance and assistance service

Processes

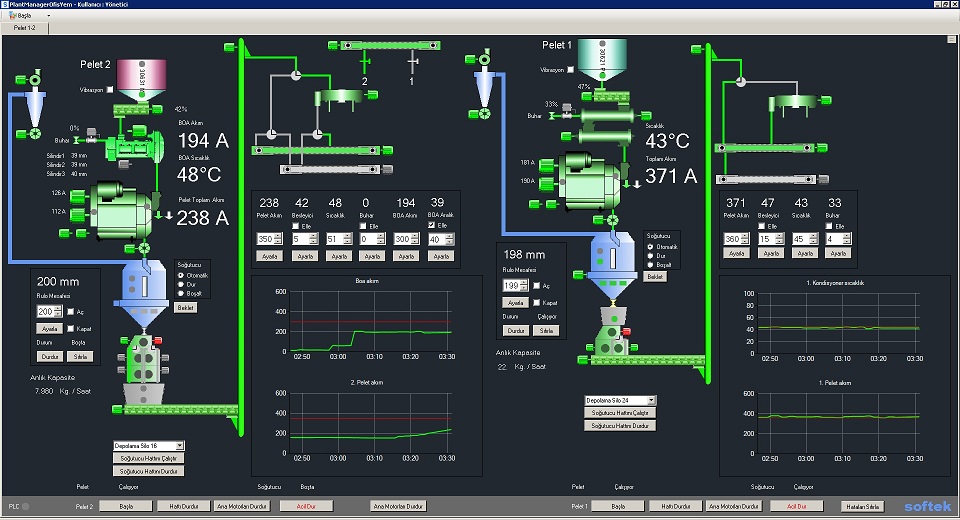

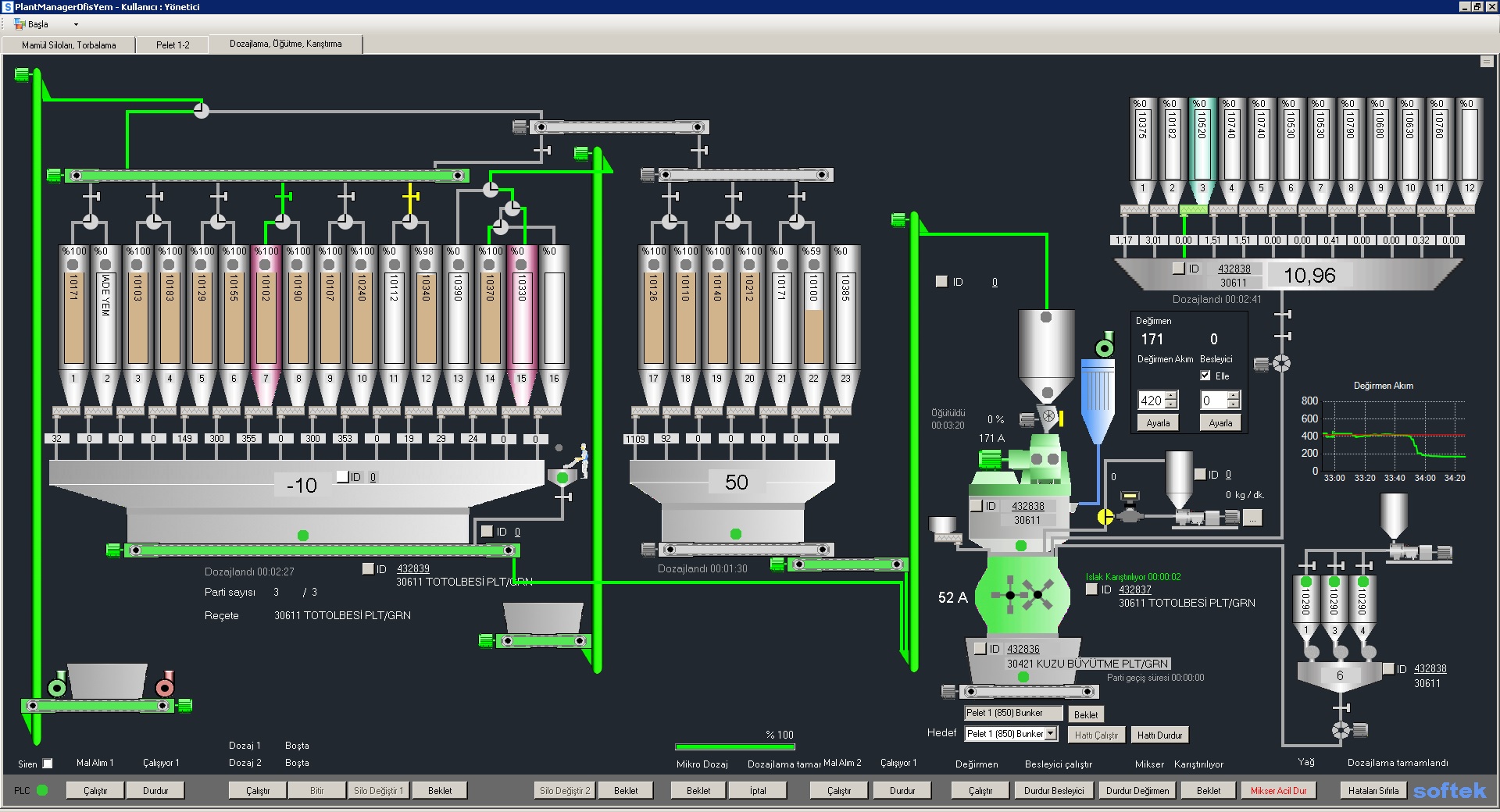

PlantManager has been developed specifically for feed mill automation. It is customized according to customer requirements.

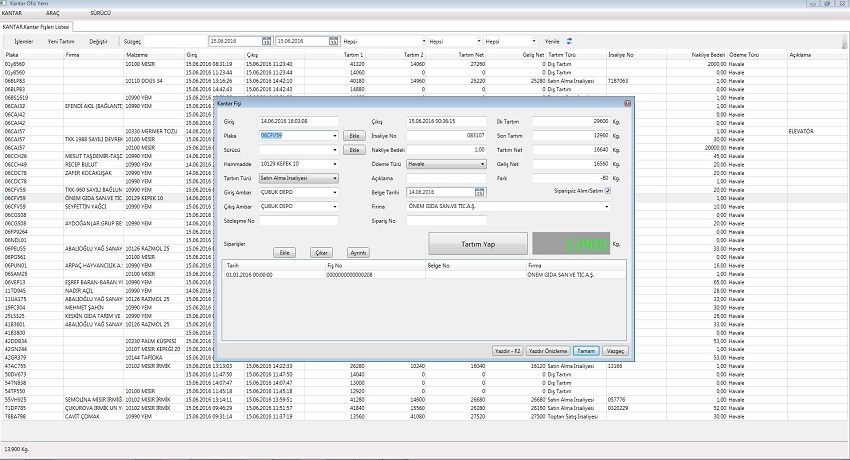

- Goods Purchase Automation

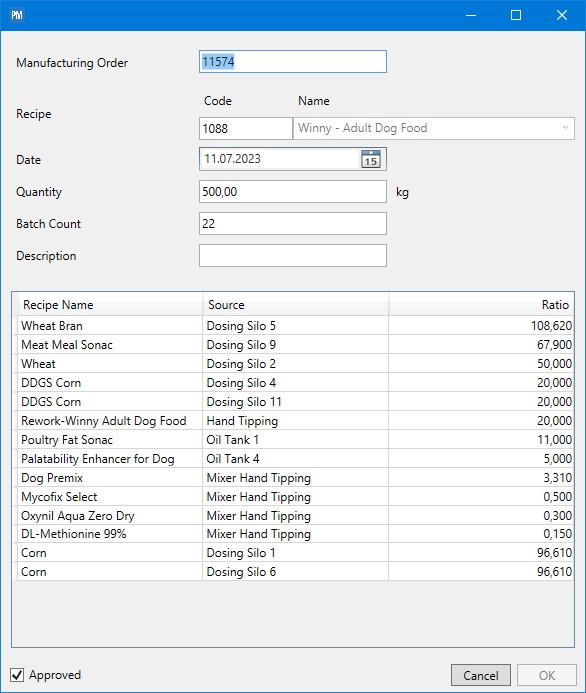

- Dosing Recipes

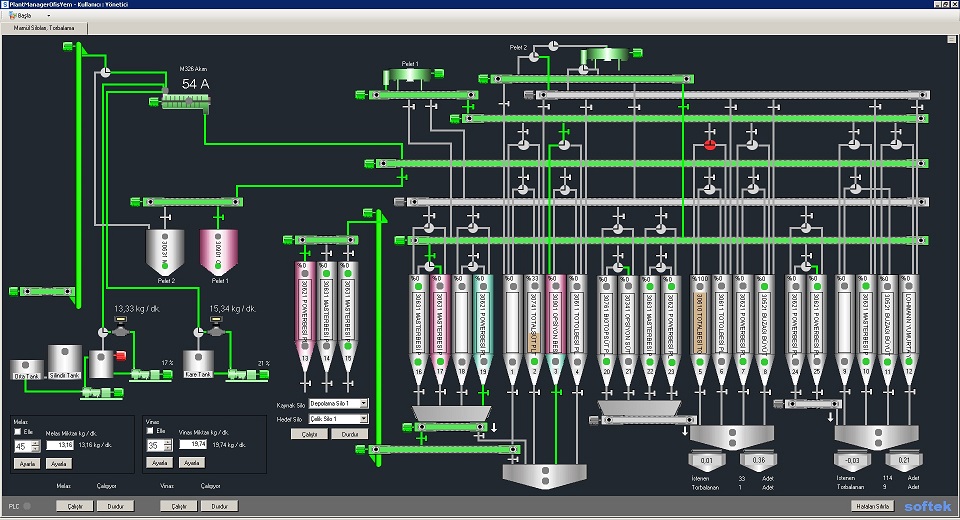

- Transport routes

- Dosing Automation

- Manual Dosing Automation

- Mill Automation

- Mixing Automation

- Liquid Addition Automation

- Pelleting Automation

- Extruder Automation

- Liquid and Aroma Coating Automation

- Packaging Automation

- BOA Compactor Automation

- Bagging Automation

- Truck Weigher Automation

- Traceability

- Liquid Coating

- Production Planning in Feed Factories

Management Functions

- Manufacturing Orders

- Dosing Recipes

- User Management and Authorization

- Event log

- ERP Integration

- Integrated Stock Control System

General features

- It runs on .Net framework.

- It is available over the Internet. The number of users is unlimited.

- It is integrated with SQL Server database.

- It has user-based authorization system and transaction log.

- It has multi-language support.

- It has traceability infrastructure.

- The system can be fine-tuned by the user using parameters.

- Faults, start and stop events are logged in the event log.

- It has Performance Monitoring System integration. KPI is calculated automatically.

Expert process knowledge

We have expert knowledge and experience on all machinery, mechanical parts, processes and problems encountered in feed factories. We work one-on-one with machine manufacturers and feed mills.

Integration and reporting

The scope of automation in factories and the reporting requirements of managers are constantly increasing. This situation requires the use of software technologies beyond traditional automation techniques. We integrate the ERP system, accounting, stock control, formula optimization software and other back office applications used in your business with the automation system and develop reports specific to your business. product silos

Testing and commissioning

The systems we have developed have passed years of field testing. In each new project, all process scenarios, inputs and outputs are tested in our laboratory before commissioning. Thus, commissioning and post-commissioning errors are minimized.

Lower costs

All software other than the operating system is our own product. We offer cost-effective solutions by not paying license fees to third-party products.

Internet

All of our products can be used over the Internet

Maintenannce Help and service

As a technology partner, we provide continuous service to our customers. We always keep your investments up to date. We provide 7x24 online help and maintenance.